- Metallurgy indstury

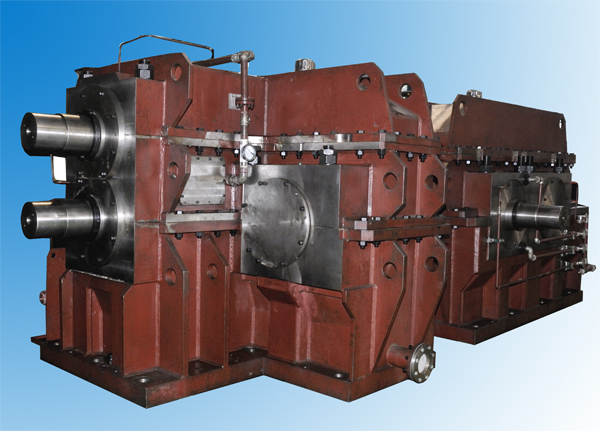

- Hot-rolled mill gearbox

Continuous hot rolling is a method of producing steel. With continuous casting slabs or blooming slabs as raw materials, firstly they areheated by a walking beam furnace, and then enter the rough rolling mill to cut the head and tail after dephosphorization by high-pressure water. Next,they enter the finishing mill, then go through the controlled rolling of real-time computer, and after the final rolling, they are coiled into straight hair coils through laminar cooling and coiling machine. The main transmission gearbox for hot strip rolling is applied into the hot strip rolling production line, which mainly provides power transmission for hot strip roughing mill, finishing mill, vertical rolling mill, including steel plate cutting head flying shear and coiling.

The reducer equipment for the main transmission device of the large hot rolling mill includes: main reducer, gear frame; rotating drum, crank-type flying shear reducer; coiler, de-coiler reducer; large drum-type gear coupling.