- Metallurgy indstury

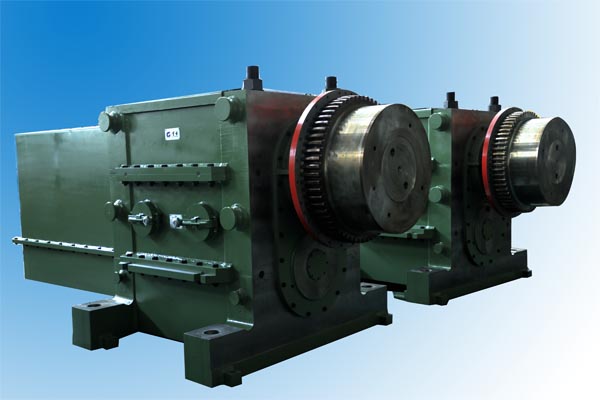

- Cold-rolled mill gearbox

In cold rolling, hot-rolled steel coils are used as raw materials, and then undergo cold tandem rolling after pickling to remove oxide scale. The finished product is hard-rolled coils. The gearbox of the continuous cold rolling unit is located between the main drive motor and the rolling mill. The input shaft is connected to the motor, and the two output shafts are connected to the work rolls of the rolling mill. Its function is to distribute the torque output by a main drive motor to the upper and lower work rolls so that the purpose of rolling cold-rolled steel sheet can be achieved.

The structure of the gearbox of the cold-rolling unit is a composite structure with single input and double output, which is equivalent to a combination of a main reduction gearbox and a base gearbox.